ceramic membranesceramic support microsieves stainless steel membranes zeolite membranes |

|

|

Asia Pacific Europe America CA MX USA |

|

CeraMem Corporation - www.ceramem.com

- 12 Clematis Avenue, Waltham, MA 02453, USA email, Tel. +1 (781) 899-4495 CeraMem Corporation is a Massachusetts Subchapter S Corporation, founded in 1986 to commercialize novel concepts for ceramic membrane modules. CeraMem's current business is primarily U.S. Government- funded contract research and development. Our customers include the DOE, NSF, DoD, EPA, and USDA. Our revenues are over $2,000,000 per year, and we have a staff of fourteen. |

Products: ceramic membranes for microfiltration, ultrafiltration

|

|

ITN Energy Systems, Inc. - www.itnes.com

- 8130 Shaffer Parkway, Littleton, CO 80127-4107, USA email: Tel. +1 303-420-1141 A team of highly skilled scientists and engineers from major aerospace corporations founded ITN Energy Systems, Inc. in 1995 to bring aerospace know-how to the commercial marketplace. We are continuing to build the strongest team of committed professionals to develop advanced technologies, such as: Fuel Cells, Ceramic Membranes, Flexible Thin Film Batteries, Nanotechnology, Advanced Photovoltaics (solar cells), Intelligent Processing -- Sensors & Controls, Industrial Waste Remediation, Desalination Program, and Equipment Design & Fabrication. |

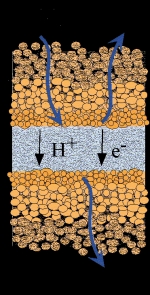

Products: Ceramic membranes for selective gas separation

ITN is applying its core expertise in the manufacturing of complex, multilayer thin film devices to novel membrane separation units and reactors to solve problems within the chemicals, fuels and environmental industries. Separation processes being developed include: - O2 from air - medical devices, chemicals processing - H2 from CO / CO2, fuels processing, H2 and power production from coal gasification - CO2 from methane, natural gas upgrading ITN is currently performing research into H2 separation membranes for the Department of Energy under the Vision 21 program. |

|

Synkera Technologies, Inc. - www.synkera.com

- 2605 Trade Centre Avenue. Suite C. Longmont, CO 80503, USA email , Tel. +1 (720) 494-8401 Synkera Technologies was formed in April of 2003 to develop, manufacture, and market innovative yet practical devices based on a combination of nanotechnology, micro and nanofabrication and advanced materials science. The company is currently focused on chemical sensors, ceramic membranes, functional nanocomposites and ceramic MEMS devices. |

Products: Microfiltration, Ultrafiltration, Nanofiltration

Synkera's ceramic membrane product group is based on anodic alumina. Unique nanoscale architecture and narrow pore size distribution are particularly beneficial to many liquid filtration and separation applications. Synkera offers three different types of membranes: symmetric, asymmetric and nanocomposite. Unique features and performance of these products are derived from the controllable nanoscale morphology and composition of the active layer(s), as well as chemical and mechanical properties of anodic aluminum oxide. These membranes are produced using our unique capabilities in extremely high precision nanoscale engineering of materials architecture and composition, following strict quality-control procedures. Our membranes find use in many fields and processes. We are currently targeting: Bioseparation, Biomanufacturing, Chemical processing, Water purification |

|

Uniceram Advanced Materials, Inc. - www.uniceramusa.com

- 3883 Rogers Bridge Road, Suite 304B, Duluth, GA 30097, USA email , Tel. +1 678 957 0896 Our company is Uniceram Advanced Materials, Inc., a provider of quality ceramic products. We have a wide array of products that serve a broad spectrum of industrial applications. Our products, typically, may be classified to seven categories on basis of their end use: Wear Resistant Parts, Insulators, Porous Filters, Refractory Materials, Other Advanced Materials, Minerals, Chemicals. |

Products: Ceramic Membrane Filters

Specially for the pharmaceutical and chemical industry, we offer the Alumina Ceramic Membrane Filters. They consist of a porous alumina support and a micro-pore membrane applied on their inner or outer surface, depending on the application. They are highly useful for solid-liquid separation, for chemical filtration and for phase separation. They are characterized by their high hardness, rigidness, chemical resistance to acid/alkali attack and high thermal shock resistance. They are highly useful in many beverage industry applications as well. |

www.membrane-guide.com keywords